Globalpesca

Request information or advice now

The project numbers

1,200 UdC

Storage capacity

Pallet e Boxes

Storage unit

Requirements

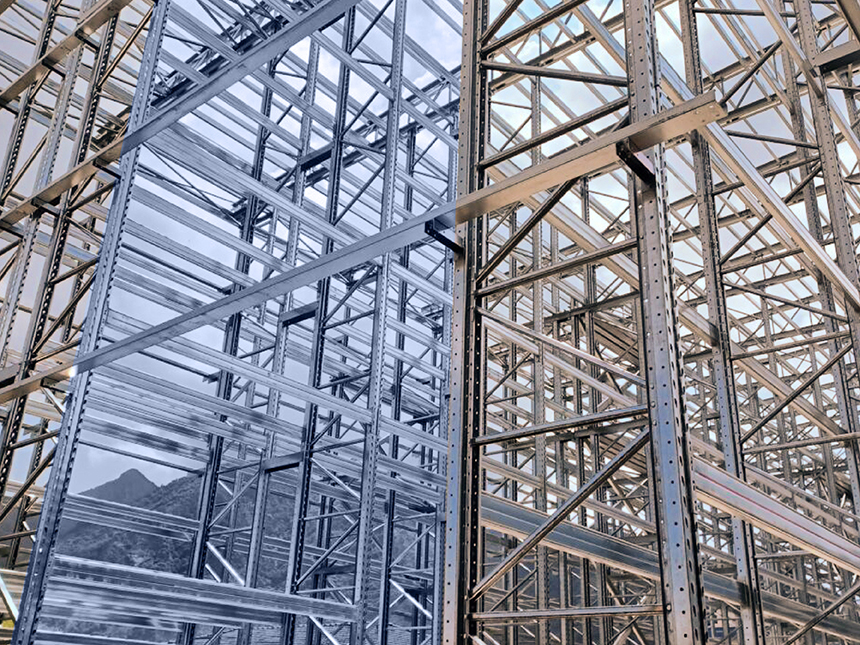

After building the self-supporting structures for the two sequencing and parcel picking towers — Smarter#1 and Smarter#2 — Dalmine LS went on to construct the self-supporting warehouse for dry goods, operated by traditional forklifts and offering a storage capacity of about 1,200 pallet positions.

This project allowed for the rationalization of space, making free the area destined for the future cold storage warehouse, which will have a capacity of approximately 3,000 pallets.

Our solutions

Globalpesca is a long-established, family-owned Italian company and a leader in the Ho.Re.Ca. sector, serving as a key reference point for Northern Piedmont and Swiss Canton Ticino. The company’s market includes hotels, restaurants, pizzerias, and catering services, to which it offers a wide range of dry, fresh, and frozen food products.

In addition to its extensive selection of fresh seafood, Globalpesca’s pride lies in its efficient internal and distribution logistics, ensuring impeccable service for its customers.

After building the self-supporting structures for the two sequencing and parcel picking towers — Smarter#1 and Smarter#2 — Dalmine LS went on to construct the self-supporting warehouse for dry goods, operated by traditional forklifts and offering a storage capacity of about 1,200 pallet positions.

This project allowed for the rationalization of space, freeing up the area designated for the future cold storage warehouse, which will have a capacity of approximately 3,000 pallets.

For all three warehouses, standard profiles were used. For the dry goods warehouse, the Bi-Bloc system was employed, featuring galvanized beams welded to plates inserted into the uprights. This method provides galvanization protection even inside the boxed sections, ensuring a much longer lifespan compared to any type of Sendzimir painting.