Menz&Gasser SpA

With three plants dedicated to Research & Development, located both in Italy and abroad, Menz & Gasser has developed a new approach to business. By supporting clients with cutting-edge technologies and high technical know-how, every Menz & Gasser laboratory is the place where rnew products are created and new ideas take shape.

To meet the quality and safety requirements set by current regulations and to align with global food trends, nutritional choices, and cultural needs of today’s consumers, Menz & Gasser has obtained, over the years, a complete range of certifications covering both processes and products.

Request information or advice now

Project figures

6.000

Pallet positions

3.500 mq

Occupied area

5

Loading levels

Pallet

Storage units

Requirements

The Sanguinetto plant needed to expand its production capacity by adding new lines and, consequently, creating new pallet spaces—both at ambient temperature and in cold storage at -25°C—for storing the raw fruit used in jam production.

At the same time, the decision was made to expand the finished product warehouse for jams, gel stock cubes, and other related products.

Our solutions

The metal structures were manufactured by Dalmine LS using Sendzimir galvanized material. The design fully complies with the current seismic regulations.

At the Sanguinetto facility, the following were installed:

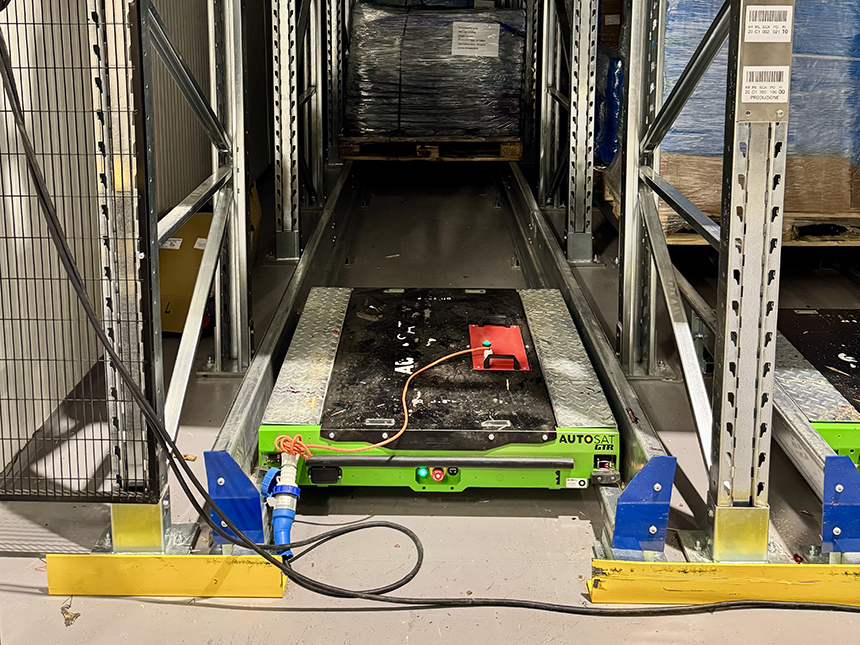

- – Multi-depth racking served by shuttle (capacity: 7 pallets deep), operated with a traditional forklift for the cold storage area.

- – LIFO push-back racking (4 pallets deep) for raw materials and certain types of finished products.

- – FIFO gravity racking for finished products, suitable for both Euro and CHEP pallets, with 20 pallets deep lanes.

- – Conventional pallet racking for both raw materials and finished products.

All racking systems are equipped with safety accessories such as meshes, stops, floor fixings, and ground guides.

Warehouse Data

Conventional Pallet Racking:

Capacity: Euro pallet positions

Levels: 5/6 + ground

Total Units (UDC): 1,700 pallets

LIFO Push-Back Racking:

Capacity: Euro/CHEP pallet positions

Levels: 5 + ground

Total Units (UDC): 772 pallets

FIFO Gravity Racking:

Capacity: Euro/CHEP pallet positions

Levels: 5

Total Units (UDC): 1,600 pallets

LIFO Shuttle Racking:

Capacity: Euro/CHEP pallet positions

Levels: 4/5 including ground

Total Units (UDC): 1,689 pallets

Gallery